In recent years, people's living standards have been increasing, and the demand for electricity resources has also been growing. In order to meet the power supply needs, high-voltage cross-linked cables have been widely used in the power system. To ensure the safe and stable operation of high-voltage cables, on-site completion handover tests must be conducted after cable laying is completed. Below, Dingsheng Power analyzes the application of variable frequency series resonance technology in cable high-voltage testing.

Cable on-site handover test

1. Test items and equipment wiring

When measuring the insulation resistance of the outer sheath of the cable core, the measuring personnel should select a suitable range megohmmeter to measure the insulation resistance of the cable according to the actual situation, in order to determine whether the insulation resistance value of the cable meets the relevant requirements.

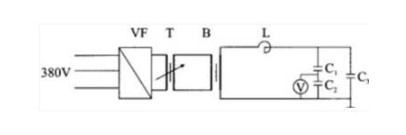

When conducting the AC withstand voltage test of cable core wire to sheath and ground, the measuring personnel should operate according to the relevant provisions of GB 50160-2006 "Standard for Hand over Test of Electrical Equipment in Electrical Installation Engineering", and the test voltage should be controlled at 2U060 min. The wiring diagram of the cable AC withstand voltage test is shown in the figure.

Among them, VF represents variable frequency power supply, T represents voltage regulator, B represents intermediate transformer, L represents high-voltage reactor, C1 and C2 represent voltage divider capacitors, Cx represents test cable, and V represents voltmeter.

2. Preparation for the experiment

Before conducting the formal experiment, the testing personnel must prepare for the experiment in order to ensure the safe conduct of the experiment. After the cable installation is completed, the first step is to ensure that the outer sheath insulation of the cable is normal and that the cable has at least one safe grounding point; If a GIS interval lightning arrester is installed at the cable terminal, the testing personnel should remove it before conducting the test, and then supplement SF6 gas. After the high-voltage test of the cable is completed, the connection of the GIS interval lightning arrester should be restored; Before the experiment, the testing personnel must ensure that the connection between the overhead line and the cable head on the outdoor terminal tower of the cable is in a disconnected state, in order to provide safety assurance for the experiment; At the same time, the secondary winding side of the current transformer must be short circuited to ground; When the GIS cable terminal side needs to be pressurized, the testing personnel must remove the GIS outlet sleeve and the main transformer connection, and ensure that the isolation switch, circuit breaker, and ground switch on the GIS cable terminal side meet the requirements of the cable high voltage test.

3. Cable high voltage test

When conducting high-voltage cable tests, the testing personnel first need to install the testing equipment at the corresponding cable terminal position, then debug the testing equipment. At the same time, the testing personnel also need to set up corresponding fences around the testing site and set up corresponding warning signs to remind pedestrians of the "high voltage danger". In the process of high-voltage cable testing, the testing personnel first need to check the insulation resistance of the cable to ensure that it meets relevant regulations; Then connect the test lead to one phase of the cable terminal joint and inspect all wiring and instruments of the test circuit; Close the test power supply, adjust the frequency of the variable frequency power supply according to the actual situation, and adjust the test circuit to resonance to ensure that the voltage regulator is in the initial position; Gradually adjust the output voltage to the test voltage and maintain it for 60 minutes, then quickly reduce the test voltage to zero and disconnect the test power supply. Hang the grounding wire at the high voltage end. During the testing process, if any abnormal phenomena such as breakdown or flashover occur, the test should be stopped in a timely manner, and the cable should be carefully inspected to confirm whether it can continue the withstand voltage test. Only by ensuring that the cable meets the withstand voltage test after inspection and processing can it provide guarantee for the safe operation of the cable in the later stage.

In order to meet the rapid development of cities, more and more overhead transmission lines are being converted into cable lines. Currently, cross-linked polyethylene cables have been widely used in urban transmission projects. In the process of cable construction, in order to ensure that the construction quality of the cable meets relevant regulations, AC voltage withstand tests are often used to test its construction quality. Applying frequency conversion series resonance technology to cable high-voltage tests can effectively improve the scientificity of the test.

Wuhan UHV specializes in the production of series resonance (also known as variable frequency resonance test device), engaged in the electrical measurement industry for many years. Its products have first-class quality and welcome customers to come and purchase