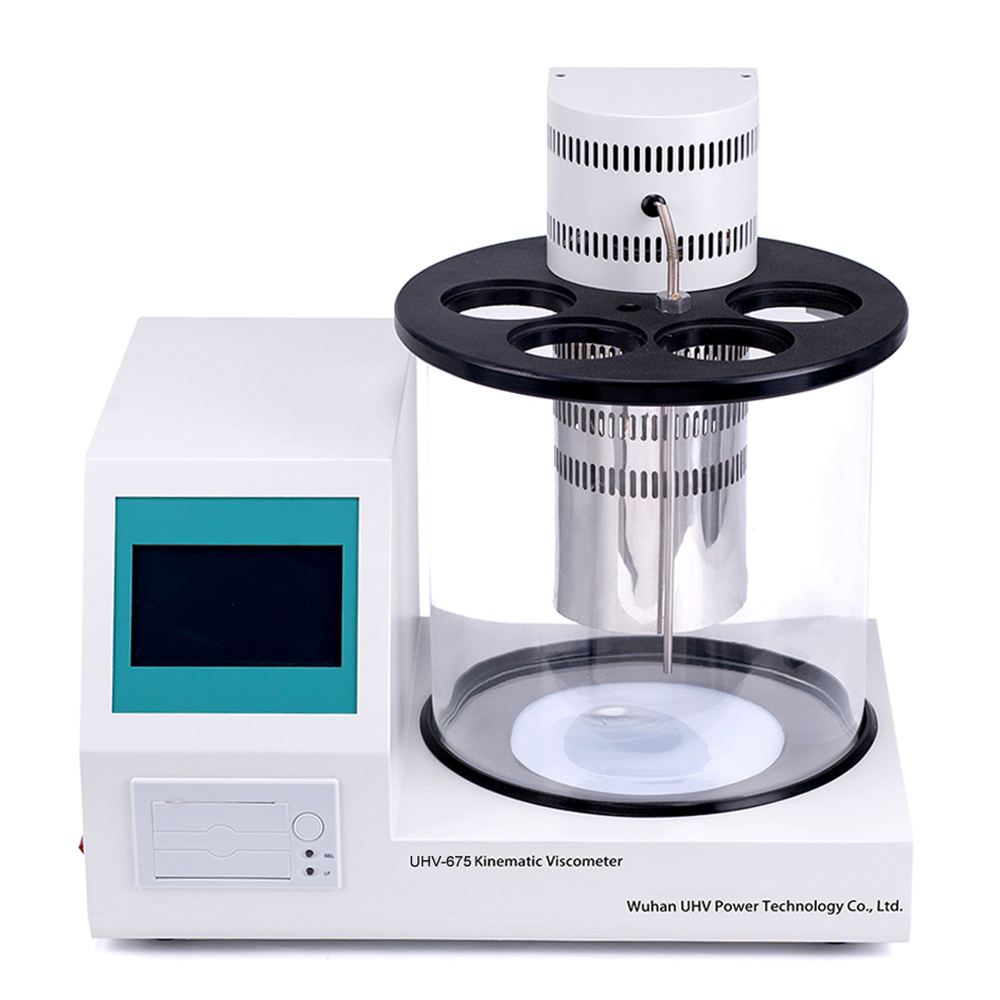

The kinematic viscosity tester under the UHV power company can help many power workers conduct various power tests more conveniently.

Automatic kinematic viscosity tester refers to a kinematic viscosity tester suitable for measuring the kinematic viscosity of transparent and opaque liquids (including crude oil, light heavy oil, lubricant additives, etc.). The operating interface is simple, and the system has advantages such as self checking, self diagnosis, and fault prediction. For your better use, I will briefly introduce the relevant usage and maintenance methods.

(1) Place the automatic motion viscosity tester on a stable workbench, connect the wires, install the sensor and thermometer, ensure that all switches are in the off position, connect the power cord, and pay attention to good grounding.

(2) When placing the capillary tube, use a heavy hammer to adjust the three screws on the capillary tube holder to make the capillary tube in a vertical position.

(3) Fill the bathtub with water until the water level is about 2cm above the top of the bathtub. If the temperature is controlled at 100 ° C, acidic or alkaline liquids should not be added to the bathtub, but glycerol can be added.

(4) Press the power switch, the power indicator light will turn on, and the water bath temperature will also be displayed. Observe whether the displayed temperature is the same as the thermometer. If there is a difference, you can adjust the device settings to the temperature required for testing (specific adjustment), please refer to the manual of the automatic motion viscosity tester for the setting method), press the mixing switch, and the motor will start mixing.

(5) When the room temperature and water temperature are above 20 ℃, if a 20 ℃ temperature control point is required, an input chiller can be used to cool the equipment. To ensure the accuracy of cooling, be careful not to put ice cubes into the bathtub.

(6) If there is fog between the insulation pipe and the bathtub that affects observation, compressed air can be introduced into the blowing pipe (note that the pressure should not be too high) or gas can be injected with a suction ball to eliminate the mist. The automatic motion viscosity tester should be kept clean regularly to prevent acid, alkali, and oil corrosion, and attention should be paid to moisture prevention. When the instrument malfunctions, it should be repaired by professional personnel and should not be disassembled at will.

The automatic motion viscosity tester does not require personnel to operate it arbitrarily. After placing the oil sample, the operator sets the oil sample number and location, starts testing, and then automatically completes automatic sampling and testing.